|

Stk

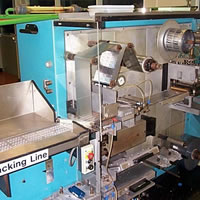

# 1304: NEWMAN FULLY AUTOMATIC LABELLING SYSTEM: MODEL CTE

250 CARTON LABELLER

The Newman CTE 250 is a fully automatic labelling system which

applies a self- adhesive tamper evident labels (security labels)

to erected cartons. The machine's compact design permits easy

integration into existing packing lines. Year of manufacture

1994. |

|

Stk

# 1301: HARLANDS LABELLER, MODEL "SIRIUS"

Front and back double sided self adhesive wrap round labeller.

Year of manufacture 1993. |

|

Stk

# 1299: KING SCREW CAPPER, MODEL: CS120 A CONTINUOUS MOTION

4 HEAD SCREW CAPPER |

|

Stk

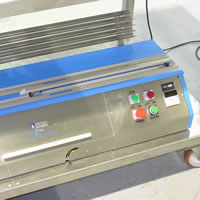

# 1265: LADY PACK MODEL 45/SL2 'L' SEALER & HEAT TUNNEL

As New. |

|

Stk

# 1241: PESTER PEWOPACK OVERWRAPPER MODEL 450SN

Fully meets GMP requirements. |

|

Stk

# 1182: UHLMANN UPS 200 BLISTER PACKER

Arranged for hand feeding, complete with a choice of change

parts for tablets and capsules. |

|

Stk

# 1149: KALFASS INTEGRATED L SEALER AND SHRINK TUNNEL

Type 5050. |

|

Stk

# 1146: M.A.R BOTTLE BLOWING MACHINE

Model MSC 20. |

|

Stk

# 1124: FARMOMAC 8 HEAD ALUMINIUM OVERSEALER FOR VIALS

Model F550

|

|

Stk

# 4000: FARMOMAC 8 HEAD ALUMINIUM OVERSEALER FOR VIALS

MODEL: F550. Rotary continuous automatic motion machine. Bottles

are fed in on a conveyor. Complete with Vibratory Bowls &

Rotary Table Fitted with safety interlock guarding and finished

in stainless steel. Output up to 9000 vials per/hr. Size Range:

Height from 54mm to 74mm. Diameter from 22mm to 30mm. Electrics:

400-440 Volts 50 Cycles Weight = 1300Kg |

|

Stk

# 4004: PESTER 'PEWOPACK' OVERWRAPPER MODEL 450SN

Collator / sleever / shrink wrapper for bottles.

Operation:

Stretchwrapping with subsequent shrinking of single or multi-packs

with PE-film.

Products:

Cartons, cans, bottles, aerosol cans, blisters, and so on.

Design:

Compact and solid modular design, integrated pneumatic and

electrical cabinet. Aluminium table surface, dynamically

stressed parts are weight-optimized. Hardened shafts with

ball bearings. All surfaces are made of corrosion-resistant

material. The machine fully meets the GMP requirements.

Large-sized guard doors. The machine is designed and built

according to the CE-specifications.

Two

metres infeed slat conveyer with Gronmeyer device for channelling

bottles from one lane into two lanes thus doubling the speed.

- 40/min single lane; 80/min twin lane conveyer.

Change

parts for size 100ml & 140 ml bottles. 90 degree pusher

collates the bottles into rows. Groups currently handled

by this machine 12 ( 4 x 3 ) and 20 ( 4 x 5 ) Machine manual

available. Fully safety guarded.

Electrics:

415V/3/50Hz

Date

of manufacture August 1988

|

|

Stk

# 4005: KING TB4 GMP ELECTRONIC TABLET COUNTER WITH ATLC

Complete with ATLC automatic, pneumatic container feed system.

Variable speed up to 40 containers per minute (depending upon

product and container). Fitted with mains on/off, variable

speed controls for tablet feed, electronic counter indicator. |

|

Stk

# 4007: KING CS 120 CONTINUOUS - MOTION 4 HEAD SCREW CAPPER

A

full assortment of change parts available ranging from 30-70mm

diameter with a 1.5m variable speed conveyor & 1m conveyor

fitted with a 360mm rotary table. Fully stainless steel

construction with fully interlocked guarding, built to GMP

standards, Mechanical cap feeders, Air operated, positive

cap pick-up chucks to apply side grip pressure no cap/no

bottle detection.

Output:

120 packs per minute.

Motor:

1 HP.

Bottle

Diameter ranging from: 18 -105mm.

Bottle

Height: 50 - 305mm.

Cap

Diameter: 10 - 50mm.

Cap

Height: 9 - 30mm.

Net

Weight: 1150 Kg.

Gross

Weight: 1350Kg.

Year

of manufacture 1999.

|

|

Stk

# 4009: CAM AUTOMATIC BLISTERPACKER MODEL M82/2

Production:

up to 540 blisters per minute depending on format size.

Mechanical

speed per minute i.e. Strokes per minute: up to 55.

The

stroke length ranges from: Minimum 115mm to Maximum 155mm.

Size

Range: Minimum 90mm to Maximum 255mm.

Blister

Length 60mm. Blister Width ranges from 30mm to 85mm. Forming

Depth ranges from 3mm to 12mm. Number of Blisters per cycle

ranges from 1 to 12 Blisters.

Power

absorption: 15Kw

Air

Consumption: 500

Gross

Weight: 3200kg

Dimensions:

H: 1800 x W: 1365 x L: 4810

Year

of Manufacture 1986

|

|

Stk

# 4014: NORDSON DURABLE 4L MOBILE GLUING MACHINE

Used

in conjunction with Nordson hot melt hoses and guns to create

a hot melt application system. The melter liquifies solid-form

hot melt and maintains the hot melt at the desired temperature.

When the guns are activated, the melter pumps the liquified

hot melt through the hoses and out the gun nozzles, where

it is commonly applied to the surface of a product.

DuraBlue

melters are specifically designed to:

i) melt

& pump solid-form hot melt materials that are engineered

to be liquified and extruded at temperatures below 230ºC

(450ºF) for 240 VAC melters or below 200ºC (400ºF)

for 120 VAC melters

ii)

Be used with compatible hot melt hoses and guns that are

manufactured by Nordson Corporation

iii)

be used in non-explosive environments

DuraBlue

melters should not be used i) to melt or pump polyurethane

reactive hot melt materials or any other material that creates

a health or safety hazard when heated ii) in environments

that will require the melter to be cleaned using a water

wash or spray

Serial

No: AN03L01494

Electrics:

240V IP32

|

|

Stk

# 4017: HARLANDS SIRIUS LABELLER

A

front and back double sided self adhesive wrap round labeller,

fitted with a variable speed plastic slat conveyor, patch

labeller with wrap round unit and scroll feed and bottle

guides & product detection & missing product sensors,

Overhead stabiliser unit removable reject bin, Air supply

filter / regulator 80psi capacity approx 60 units per min.

The base unit consists of fabricated steel frame clad with

stainless steel support plates. Electrical supply: 240v

/ Phase 1 / 50Hz via mains supply. Year of manufacture 1993.

|

|

Stk

# 4019: KING LH5 FULLY AUTOMATIC LABELLING MACHINE FITTED

WITH ARGUS 3 BAR CODE READER

Applies

pressure sensitive labels to all shapes of containers including

plastic, glass & aluminium etc.The basic machine will

label round containers, single panel labels on square or

rectangular containers and spot labels on oval shaped examples.

Containers

of up to 153mm diameter by 254mm high can be handled in

the standard set-up giving a wide range available for labelling.

Electrical

requirements: 2 KW

Container

handling range: Diameter - 20mm to 150mm Height - 20mm to

250mm

Output:

Up to 300 per minute

Net

weight: 750kg Gross weight: 900kg

Case

size: 300cm x 130cm x 170cm

Year

of manufacture 1988

|

|

Stk

# 4021: KUGLER AUTOMATIC MODEL: K 705 - S8 8 HEAD SCREW

CAPPER WITH A SIEMENS PLC CONTROLLER

Fitted

with a scroll infeed & vibratorybowl cap feeder.

Capping

heads: 8

PLC:

SIEMENS CP6

Working

direction: left to right

Setings

range: 4,200 / 16,800 units per hour

Effective

output: 9,000 units per hour

Power

consumption: 3 phase - 230 / 240v - 50Hz

Year

of manufacture: 1998

|

|

Stk

# 4023: QUALISEAL LABORATORY CAPSULE SEALING MACHINE

The

Qualiseal is designed to seal the joined portion of the

cap and body of filled hard gelatine capsules.

Capable

of sealing capsules sizes: 00, 0, and 1,2,3,4

Power:

115 VAC 50/ 60 Hz 3 Amps

Dimensions:

Width: 737mm x Depth: 304mm x Height: 305mm

Weight:

30kg

Year

of manufacture: 1999

|

|

Stk

# 4027: AUTOMATED PACKAGING HS-100 EXCEL BAGGING UNIT

The

HS 100 - EXCEL bagging unit feeds empty polythene bags mounted

on a roll into the bagging area. The unit is intended to

feed, open, seal, and separate poly bags. At the bagging

area the bag is opened by a pulsed jet of compressed air,

filled with product(s) and sealed.

In automatic

mode the bags are filled and sealed automatically. In manual

mode the bags are filled manually and the sealing function

is activated by means of a foot switch. Bag sealing occurs

when the pressure bar compresses the top of the bag against

a teflon covered heating element.

The

unit requires a air supply of 80 PSI (5.5 bar)

The

unit can be ser to use either 110 or 240 Volt electrical

power supplies.

|

|

Stk

# 6001: VIDEOJET EXCEL 170i INKJET PRINTER

A

continuous stream, non-contact ink jet printer. The Series

1701 UHS can code virtually any surface, texture, contour

or shape. Printing is controlled through the built in keyboard

allowing a wide variety of print features including: one,

two, or three lines, Upper and lowercase letters, store

messages, multistroking (offering varying bold single-stroked

lines), reverse print, inverted print, current time and

date / auto expiration date, print a bar code, insert a

graphic character or design, print a serializer (successive

numbering), print a code in the same location on each product,

regardless of product etc.

Electrics:

100-240V - 2-1amps - 50/60Hz - single phase.

Air

Requirement: 100 psi / 6.9 bar.

Year

of Manufacture: 1999

|